STLR Model [1]

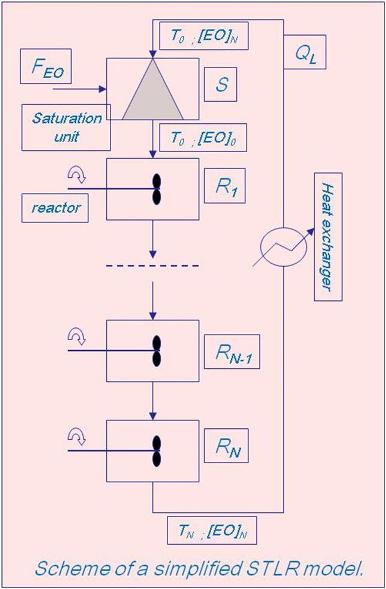

In STLR, the sprayed liquid is dispersed in the form of small liquid drops flying into the alkylene oxidegaseous atmosphere. Drops emerging from an efficient spray nozzle resulted as internally well-mixed drops, leading to a very high mass-transfer rate, and if the average flight time of the drops is long enough, these drops are completely saturated at the end of their flight. In all cases when flight times are much shorter than the ethoxylation reation time (fraction of seconds), the extent of the reaction occurring inside the drops can be disregarded. Hence, in these reactors, mass transfer and chemical reaction occur separately in two distinct zones of the reactor: the mass-transfer zone, corresponding to the zone of drops flying across the gaseous atmosphere, and the reaction zone, corresponding to the slowly flowing liquid-phase collected at the bottom of the reactor. The reaction zone can be simulated as a plug-flow reactor. However, the reactor operates in semibatch conditions, and transient conditions are present, so a rigorous simulation of the reactor requires a solution to a system of partial derivatives. The model can be simplified considering a first stadium of liquid saturation followed by a series of N well-mixed reactors of small volume (reaction cells), operating in a loop.

1- Industrial & Engineering Chemistry Research (2005), 44(25), 9482-9489.