The role of ethylene oxide solubility in the ethoxylation process was studied to determine the influence on both the kinetics and the behavior in different reactors [1,2]. The key factors in alkoxylation technology were examined [3-6]:

- (i) the types of reactors employed and their performances;

- (ii) the role of kinetics and mass transfer in the process;

- (iii) the safety problem.

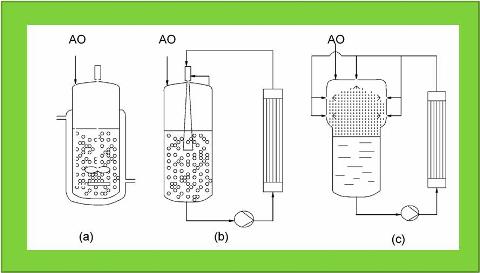

The reactors widely employed in industry can be classified as: (a) Semibatch Stirred Tank Reactors; (b) Venturi Loop Reactor and (c) Spray Tower Loop Reactors.

In the first two types of reactors, the gas phase is dispersed into the liquid phase; on the contrary, in the latter case, the liquid phase is dispersed into the gaseous one.

1- Catalysis Today (1995), 24(1-2), 23-28.

2- Industrial & Engineering Chemistry Research (1995), 34(11), 4092-4098.

3- Chemical Engineering Science (1999), 54(10), 1499-1504.

4- Industrial & Engineering Chemistry Research (2000), 39(11), 4082-4093.

5- Industrial & Engineering Chemistry Research (2005), 44(25), 9482-9489.

6- Journal of Loss Prevention in the Process Industries (2007), 20(3), 238-250.