A. Barone, B. Anna De Liso, H. Grénman, K. Eränen, F. Taddeo, C. Imparato, A. Aronne, V. Russo, M. Di Serio, T. Salmi

Processes 2024, 12(1), 27; https://doi.org/10.3390/pr12010027

Abstract

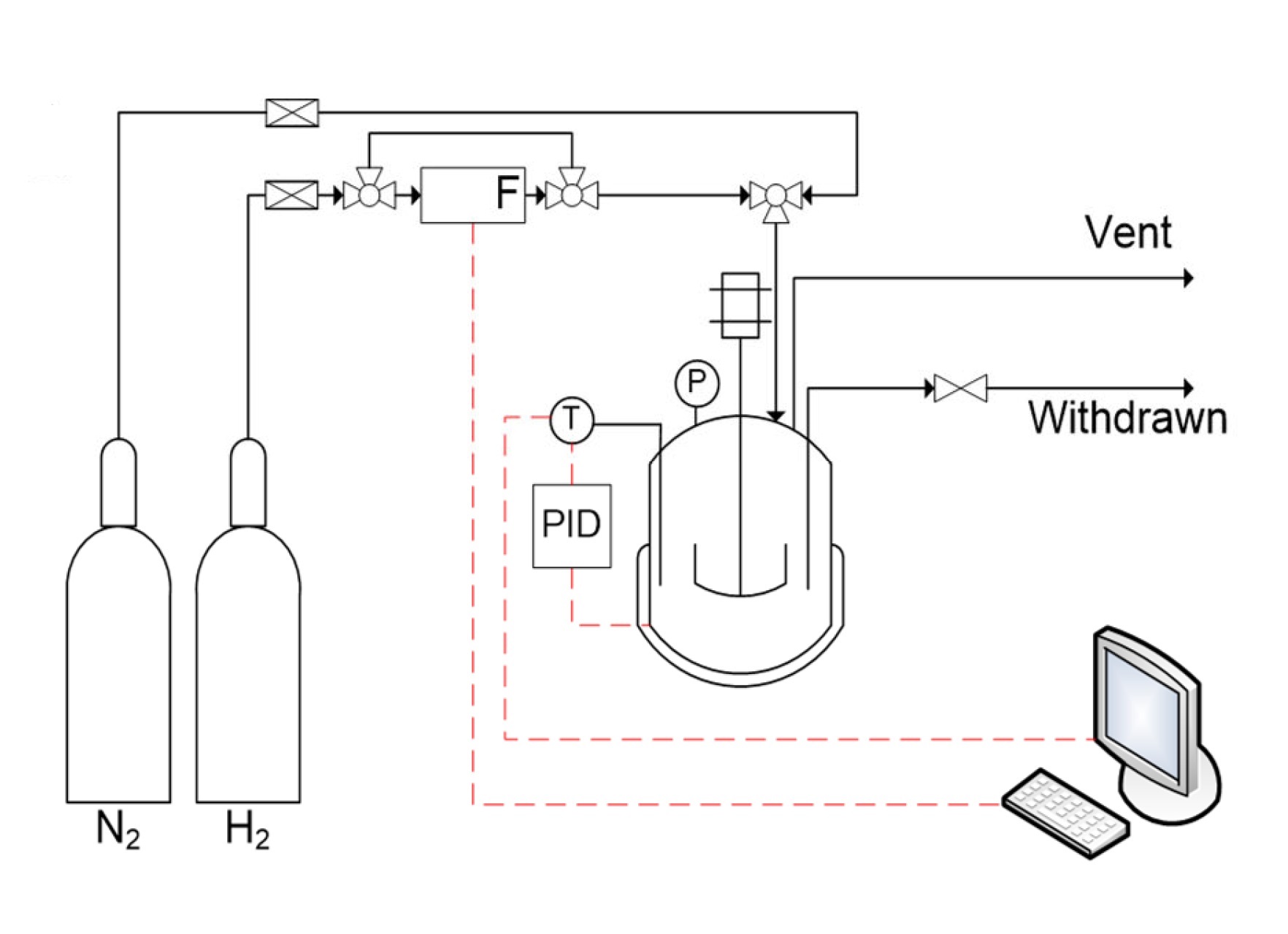

Xylose is nowadays converted into xylitol, a popular special chemical sweetener. Xylitol can be used not only in the pharmaceutical and food industries, but also in cosmetics and synthetic resins because of its countless properties. Conventionally, xylitol is produced by slurry reactors operating in batch with dispersed or supported catalysts. Hydrogen is continuously fed to maintain a constant pressure. In this work, the kinetics of the reaction were investigated to find the optimal operating conditions to minimize the by-products obtained. Given the great performances shown by the new Ru/SiO2 sol–gel derived catalyst in glucose hydrogenation, in this work the mentioned catalyst was tested in the hydrogenation of xylose to xylitol both in batch and in continuous production to prove its stability and activity.