Novel insights into acetylation kinetics in a continuous Flow milli-reactor for chemo-enzymatic separation of silybin A/B

Michele Emanuele Fortunato, Rita Pagano, Valeria Romanucci, Chiara Licenziato, Armando Zarrelli, Martino Di Serio, Giovanni Di Fabio, Vincenzo Russo

Journal of Flow Chemistry, 14, 585–595

https://doi.org/10.1007/s41981-024-00329-w

Abstract

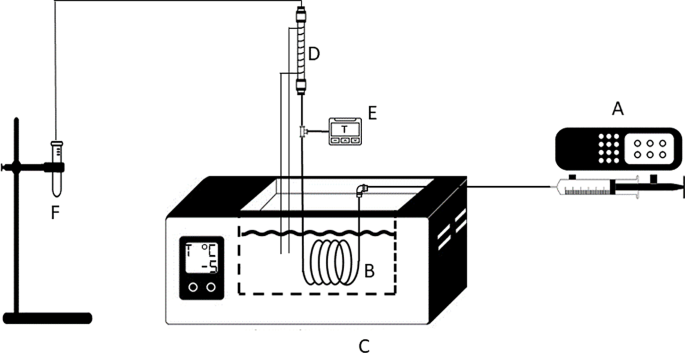

The separation of silybin A (SilA) and B (SilB) diastereomers in optically pure compounds is challenging due to their very similar physical and chemical properties. However, such separation is crucial for evaluating the biological activity of the diasteroisomers SilA and SilB, which show very different performance in pharmacological applications like treating prostate cancer, liver diseases, and Alzheimer’s disease. The most common isolation method is based on high-performance liquid chromatography, but it is slow and has a yield in pure SilB of hundreds of milligrams per day. An alternative chemo-enzymatic separation method, utilizing an immobilized lipase CALB catalyst to stereoselectively acetylate silybin B (1b), offers advantages in terms of higher productivity, selectivity, and scalability, particularly when applied in flow reactors. This study delves into the kinetics of Sil acetylation catalyzed by Novozym 435 in a continuous flow milli-reactor, investigated at various temperatures, volumetric flow rates, and Sil initial concentrations. It is noteworthy that, at the current state of the art, there is a lack of kinetic studies on this reaction, emphasizing the novelty and significance of this work. The kinetic and fluid dynamic parameters were estimated using a non-linear regression analysis of experimental data. The examined reaction showed a null apparent activation energy, explaining the temperature insensitivity of the final acetylated silybin B (1b) concentration. Furthermore, the decrease in steady-state concentrations of the acetylated products with increasing volumetric flow rates indicated that the reaction was occurring in a kinetic regime. Interestingly, a maximum starting Sil concentration was identified, above which there was no favorable impact on conversion.