Vincenzo Russo, Riccardo Tesser, Wiesław Hreczuch, Martino Di Serio

Chemical Engineering Research and Design (2023) https://doi.org/10.1016/j.cherd.2023.04.051

Abstract

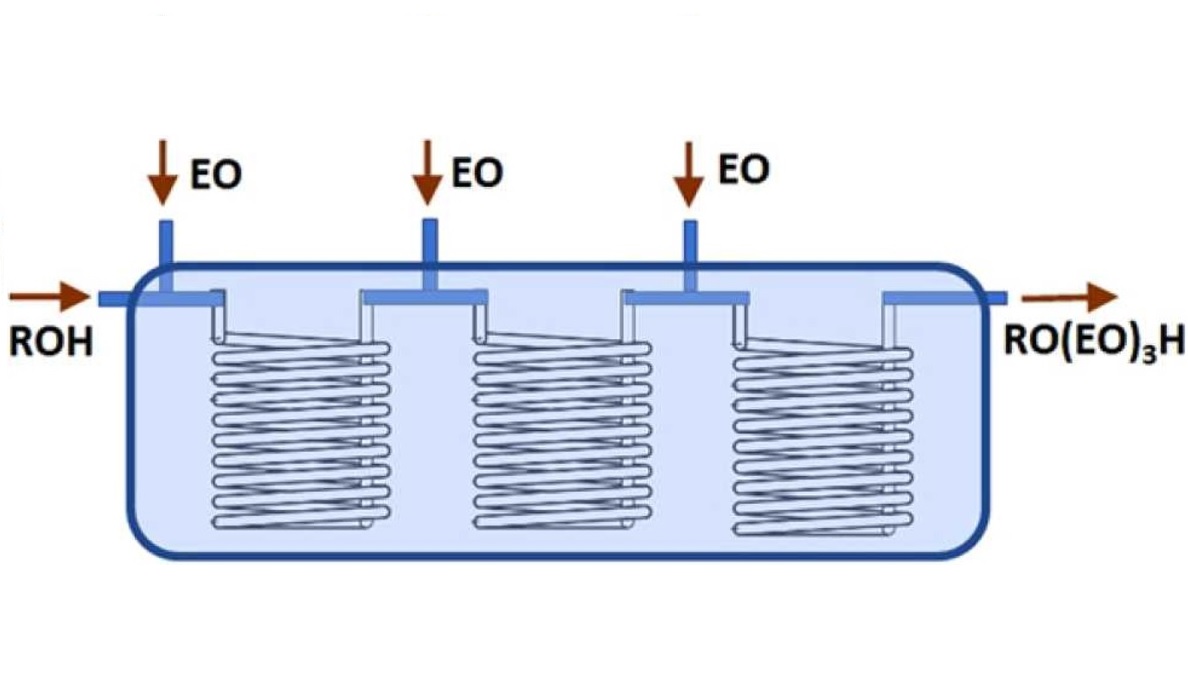

– A laminar flow model was developed to investigate the reaction kinetics of 1-dodecanol ethoxylation promoted by KOH, elaborating the data collected in microreactors. A generic laminar flow model was coded, and a sensitivity analysis was conducted highlighting the good flexibility of the model to simulate a wide range of conditions. Ethylene oxide diffusivity and liquid mixture viscosity were determined by applying existing correlations, carefully considering the change in viscosity with ethylene oxide conversion, temperature, and feed ethylene oxide/1-octanol ratio. The model was tested on literature data obtaining in every case good results. The obtained kinetic data were demonstrated to be in line with the ones obtained in separate investigations conducted in a fed-batch reactor, demonstrating that there was a real need in adopting the laminar flow reactor approach, as it allowed to retrieve of more precise information about the intrinsic kinetics of the ethoxylation reaction, when working with microreactors, compared with the ones obtainable with a plug-flow ideal fluid-dynamic model. The developed model was used to simulate the behavior of a milli-reactor (this device allows to reach sufficient productivity for industrial application) and it was forecasted the possibility to use continuous ethoxylation milli-reactors using fluid-dynamic conditions characterized by a high Reynolds number (>10000).