A technoeconomic assessment of biological sludge dewatering using a thermal rotary dryer: A case study of design applicability, economics, and managerial feasibility

Amjad El-Qanni, Mohammed Alsayed, Ihab H Alsurakji, Mohammad Najjar, Diana Odeh, Saja Najjar, Maryam Hmoudah, Mukarram Zubair, Vincenzo Russo, Martino Di Serio

Biomass Conversion and Biorefinery (2024) 14, 12, 13055-13069

https://doi.org/10.1007/s13399-022-03480-3

Abstract

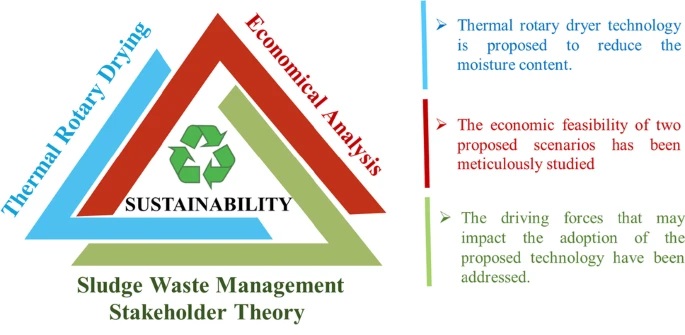

The shortage of freshwater in Palestine and the huge competing demands from a variety of users stimulate an urgent need for finding cost-effective, sustainable, and environmentally friendly solutions for the current wastewater treatment processes. For instance, the anaerobic dewatered biological sludge (hereinafter called sludge) produced from wastewater treatment plants (WWTPs), in the West Bank, is considered challenging. To date, the only legal way of sludge disposal is in landfills. This is considered an obsolete solution due to the lack of landscape and improper solid waste management actions. In this study, sludge produced by a WWTP located in Nablus city has been considered. The daily capacity of sludge production at this plant is approximately 15 tons/day. This sludge is usually transferred in huge trucks and eventually dumped in a landfill called Zahrat Al-Finjan (ZL). This process costs about 45,000 ILS/month (~ $12,800/month) with the possibility of generating many hazardous emissions. In addition to this solid waste problem, this WWTP produces biogas as a by-product. Herein, a thermal rotary dryer technology is proposed to reduce the moisture content from 70 to 10% to meet Palestinian environmental regulations; thus, processing of such dewatered sludge can be feasible for further uses rather than dumping in landfills. The main objective of this work is to present a case study of the applicability, sustainability, and economic feasibility of such a proposal. Two scenarios related to thermal drying are investigated; the first one considered the use of hot exhaust air (490 °C) that comes from the combined heat and power (CHP) unit, which promotes the energy integration approach, while the second scenario adopted the use of external sources of heat (fuel mainly the natural gas). The results of the economic analysis revealed that the first scenario was more efficient and feasible with a net present worth of around $100 k with a simple payback period of 2.7 years. The obtained design parameter, mainly the length to diameter ratio, was around 9.6 with a retention time of 1.8 h. Though these values are within the conventional rotary thermal dryers, one may ask how to convince stakeholders to implement such an approach practically. Therefore, sludge waste management along with technological adaptation was also thoroughly studied via stakeholder theory.