Logo NICL

PRODUCTION OF YEAST

A general kinetic and mass transfer model to simulate the growth of bakerís yeast in bio-reactors [1-3]

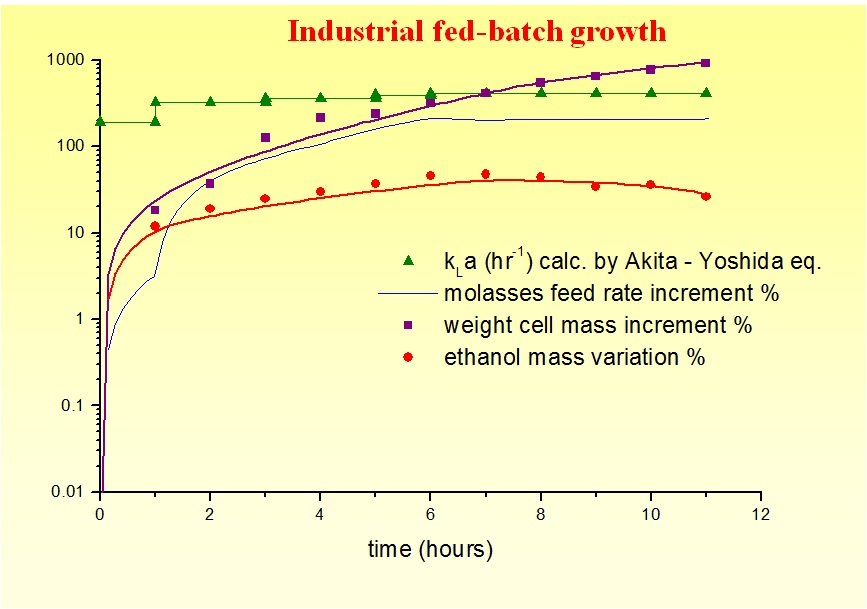

The industrial bio-reactor is a bubble column several meters in diameter. The simulated production refers to a first fed-batch step. Since the final bio-mass concentration is lower than 20 g/L, we consider the fluid-dynamic behaviour of the suspension similar to that of water, so we have calculated the mass-transfer coefficient in the bio-reactor using the well known equation of Akita and Yoshida. In this figure we illustrate the experimental data of bio-mass and ethanol weight percentage variation and the percentage increment of the molasses addition rate over time. In the same figure we have reported the calculated values using the cybernetic model with parameters taken from the literature and the mass-transfer coefficient calculated with the Akita and Yoshida equation. From the good agreement obtained, and from other tests on industrial production that we have not reported here, we can conclude that the cybernetic model can be a useful tool to simulate the industrial bio-reactor.

[1]Industrial & Engineering Chemistry Research (2003), 42(21), 5109-5116.[2] Catalysis Today (2001), 66(2-4), 437-445

[3] Chemical Engineering Journal (2001), 82(1-3), 347-354.