Logo NICL

PRODUCTION OF YEAST

A general kinetic and mass transfer model to simulate the growth of bakerís yeast in bio-reactors [1-3]

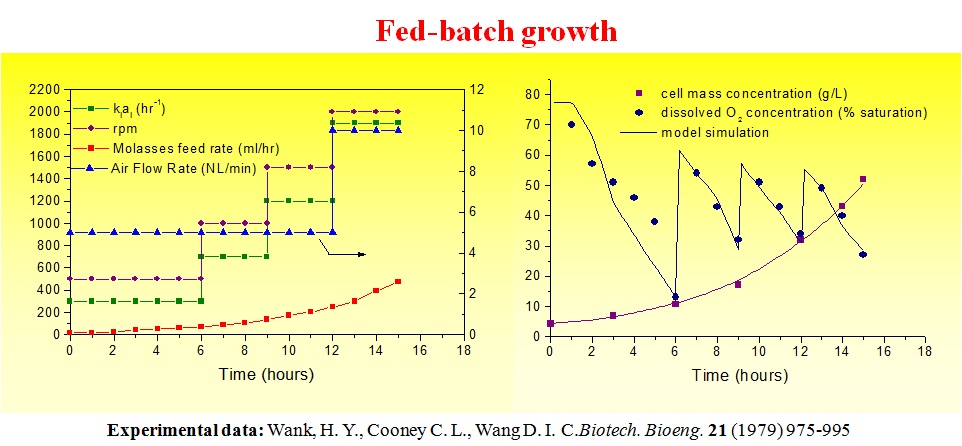

The run was conducted with a feed control to maximise the yeast yield, i.e. in conditions that favor the oxidative sugar metabolic pathway, that is sufficient oxygen in the liquid phase and low sugar concentration in the growth medium. In order to ensure full aerobic conditions during the run, both air flow and stirring rate were varied to keep the dissolved oxygen concentration higher than 15 % of saturation, the critical value established by Wang. The results obtained are shown in the figures. In the first figure we can see the employed experimental condition of molasses feed rate, air flow and stirring rate, and the related oxygen mass-transfer coefficient used in the simulation. The experimental data of bio-mass and oxygen concentration are reported in the second figure, where we can also see the good fit obtained with calculated values. The prevalent metabolic pathway in this case is the oxidation of sugar, as foreseen by the Crabtree effect, so we can conclude that this effect has also been well described by the cybernetic model. The same conclusions have been reported by Jones and Kompla, who employed a cybernetic model to describe batch and continuous runs.

[1]Industrial & Engineering Chemistry Research (2003), 42(21), 5109-5116.

[2] Catalysis Today (2001), 66(2-4), 437-445

[3] Chemical Engineering Journal (2001), 82(1-3), 347-354.